Revolutionise Your Logistics: Introducing the Talk and Pick System!

Whether you’re a traditional retailer or a new online business, the challenges are the same: high productivity, low operational costs, and consistent customer satisfaction. Operating at peak efficiency is essential to achieve these goals in the rapidly growing e-commerce and retail sectors but seemingly daunting to achieve.

Cost of Inefficient Operations

Unlike product acquisition, channel fees, shipping, and taxes, some costs, such as the Cost Per Pick in your warehouse, often go unnoticed. The Cost Per Pick is the total cost incurred for picking a single item from your warehouse, including labour, time, and potential errors. These costs can quickly add up. As your business expands, controlling the Cost Per Pick becomes increasingly critical. In an inefficient warehouse using paper systems, employees spend significantly more time picking each item, resulting in unnecessary labour costs. These inefficiencies will likely worsen without an automated analytical system to monitor and optimise daily operations.

Cost of Errors

Warehouse errors can be costly. These issues disrupt the flow of goods, cause financial losses, and damage a company’s reputation. Picking errors can have a knock-on effect: They can lead to shipping mistakes and ultimately decrease customer satisfaction, resulting in lost sales.

These returns are costly and involve documentation and return shipping. They often require customer service staff to appease customers and sales staff to waste time addressing complaints, forcing the team to focus on appeasing customers instead of securing new sales. Warehouse labour costs rise due to restocking and wasted hours. Picking errors often mean stocking errors, necessitating cycle counts at affected locations.

Monetised Operations

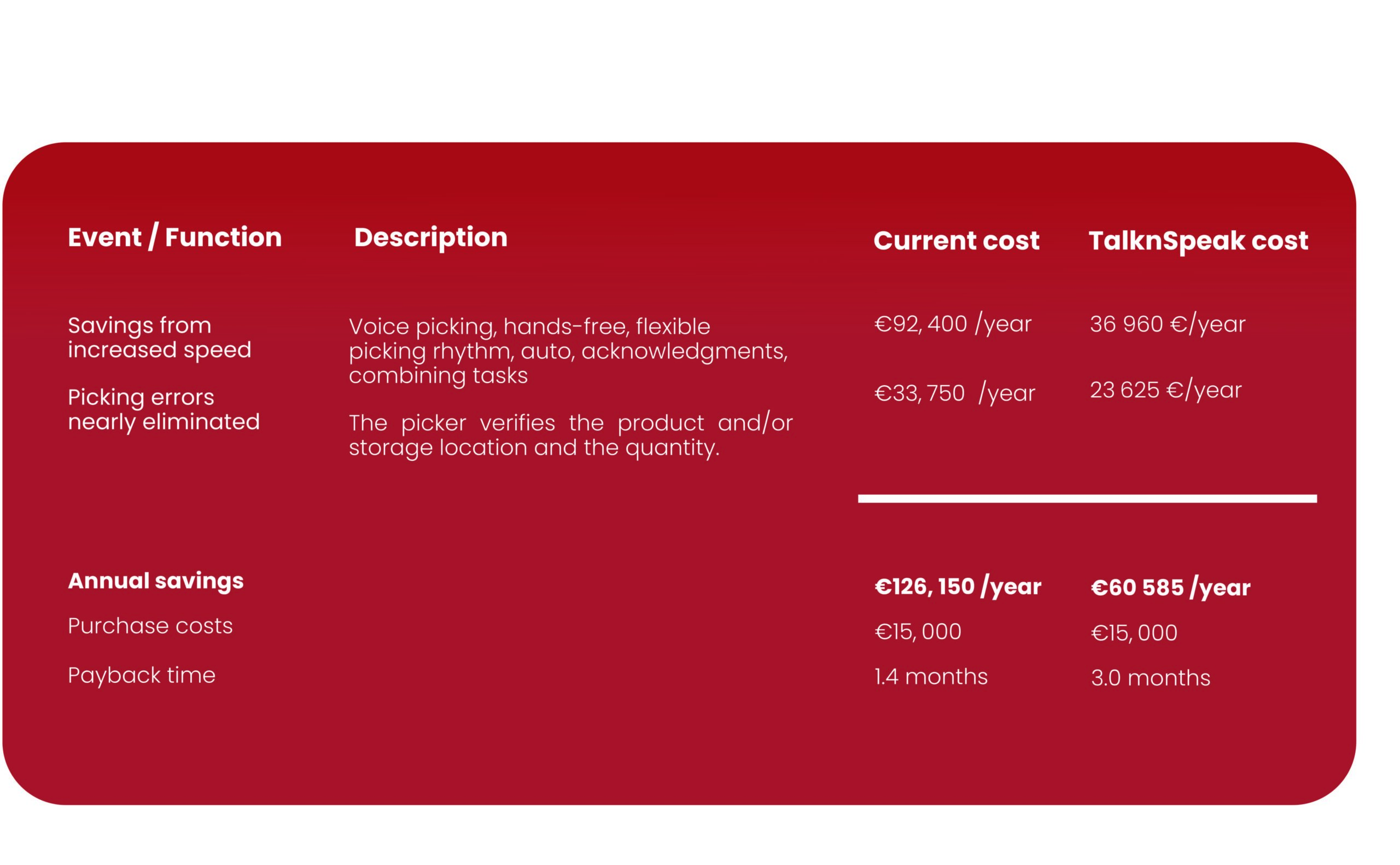

Deciding to automate your warehouse is a big decision, but reducing the Cost Per Pick is crucial for protecting and growing profit margins. Streamlining ordering procedures, effective return routines, and a consistent logistics system are essential for success.

Talk and Pick is the best end-to-end solution, surpassing traditional warehouse systems. It’s incredibly easy to use, with training taking just 15 minutes!

This powerful new technology can create 40% more operational efficiency and 80% more accurate warehouse picking.

By embracing efficient practices and leveraging innovative solutions, businesses can streamline operations to maintain short delivery times, low error rates, and excellent service levels, instilling confidence and security in their operations.

The wearable solution of Talk and Pick liberates your hands and eyes, enhancing safety as employees can use their hands for handrails while climbing ladders and navigating hazards. This not only increases safety but also empowers your workforce, making them feel more secure and in control.

Benefits

Reduce labour costs, the most significant expense

Decrease picking errors by up to 80%

Voice picking for hands-free operation

Streamline warehouse processes

Optimise operations

Increase transparency

Enhance task predictability

Talk’nPick elevates warehouse management from start to finish.

This convenient, browser-based solution optimises, manages, and tracks warehouse work in real time. It provides real-time monitoring and comprehensive reporting, helping streamline operations and free staff for other tasks. Talk and Pick removes the stress from daily tasks, offering a simple and user-friendly interface without heavy updates or complex software.

Our solutions enable continuous inventory, dynamic inventory management, and automated transportation management. The ability to analyse analytics empowers businesses to strategize effectively, driving efficiency improvements.

Features

Receipt, shelving, picking, inventory, and internal transfers

Powerful search functions and versatile data confirmation

Multimodal use: speech, barcode/QR code, RFID, typing

Task optimization: route optimization, aggregate picking, area picking

Printing: product labels, bin locations, other labels

Device independent: smartphones, PDAs, tablets, AR devices, finger scanners, pocket scanners, Bluetooth headsets

Network independent: Wi-Fi, GSM, Wi-Fi + GSM

Versatile integrations: voice picking interface, built-in integration, standardized REST interface, custom integration

And best of all, the payback period for acquiring this solution is often less than a year. Talk and Pick isn’t just about reducing costs—it’s about advancing your company’s position for sustained growth.