Charles River Microbial Solutions Transforms Warehouse Efficiency with the Tornado Vertical Lift System

We are so excited to showcase one of our largest projects this year for the distinguished “Charles River Microbial Solutions International Ltd”. Charles Rivers has been making waves in the healthcare world since 1947 with 21,000+ employees and over 150 facilities across the globe, they’re a major player in supporting pharmaceutical, biotechnology, agrochemical, government, and academic organizations.

When their Dublin facility needed a more efficient and streamlined way to manage growing storage demands, Charles River turned to us for a sophisticated storage solution that would not only improve batch picking operations but also enhance security and precision. Faced with increasing demands, they sought a system that could optimize workflow, ensure fast, accurate inventory management, all while seamlessly integrating into their operations and meeting the scrupulous compliance requirements of the pharmaceutical industry.

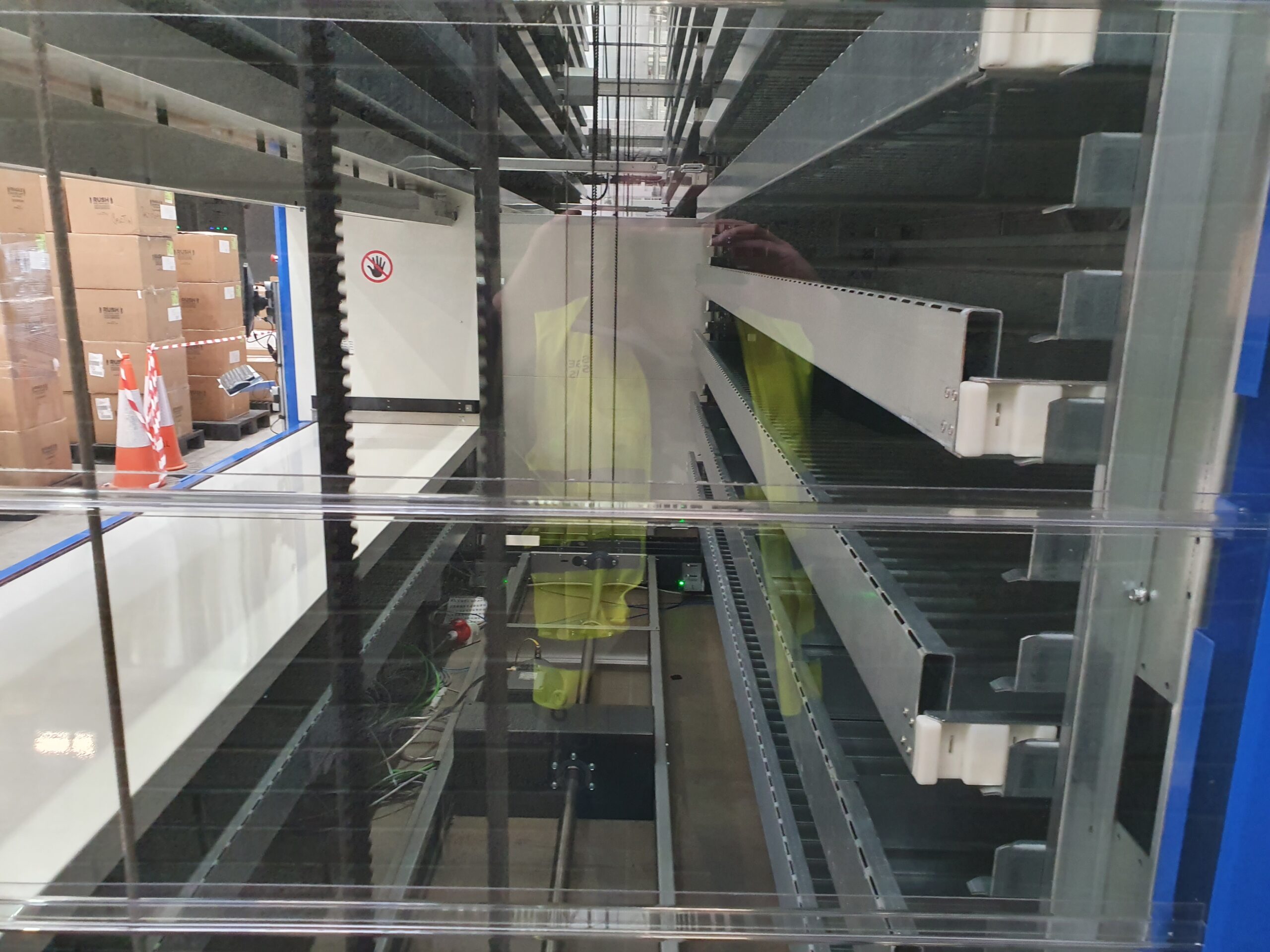

The Solution: Tornado Vertical Lift Systems

Like its name suggests, the Tornado Vertical Lift System operates as an advanced Batch picking Solution, unrivalled for speed. This dynamic vertical storage solution offers maximum storage capacity with minimal floor space, delivering fast and efficient access to goods. However, unlike a real tornado, the system ensures complete control, precision, and reliability.

Charles River partnered with Storage Systems Ltd. to implement the Tornado, which brought a range of valuable benefits:

- Up to 75% floor space savings while providing the same storage capacity, allowing Charles River to use their space far more efficiently.

- Fast and accurate order performance: The system guarantees efficient and precise order picking, improving overall operational speed.

- Ergonomic “Goods-to-Person” operation: This principle reduces manual transport routes for operators and speeds up picking processes, ensuring less strain on staff and quicker fulfilment.

- Reduction in picking errors: Enhanced accuracy and technology integration have dramatically minimized mistakes in order processing. Therefore eliminating any associated costs and safeguarding brand integrity.

- Password-protected access levels: The system offers added security with restricted access for authorized personnel only.

- Minimized order throughput times: The efficiency of the Tornado has drastically reduced the time it takes to process and fulfil orders.

- Remote support capability: The Tornado system can be accessed remotely, allowing fast troubleshooting and expert support without needing an on-site visit.

- Windows-based WMS system: The user-friendly TC2000 PRO warehouse management software allows for easy integration with existing IT systems, ensuring smooth operations across platforms.

The Results: Boosted Productivity and Accuracy

- The installation of the Tornado system produced immediate, impactful results for Charles River:

Faster Pick Times: The automated system reduced the time spent retrieving materials, improving the team’s ability to fulfil orders quickly. - Improved Inventory Accuracy: By integrating the TC2000 PRO software, Charles River achieved better stock control, reducing errors and enhancing overall efficiency.

- Reliable, Proactive Support: Remote support capabilities allowed for rapid issue resolution.

“The Tornado system has completely transformed our warehousing operations. It’s fast, efficient, and has allowed us to improve both our pick cycle times and inventory accuracy. The after-sales support from Storage Systems Ltd. has been outstanding. If any issues arise, their team is quick to respond, and most problems are resolved remotely, minimizing disruption to our operations.”

John Geraghty, Operations & Logistics Manager

Charles River